Sewing needles are the backbone of any fabric project. The right needle can make all the difference in the quality and finish of your work.

Understanding the different types of needles and their specific uses guarantees professional-looking results and ensures a smooth sewing process.

In this article, you will find everything you need to know about sewing needles, their types, sizes, purpose, appropriate use, care, and maintenance.

Types of Sewing Needles

Sewing needles can be of two main types: hand-sewing and machine needles. Each type has its unique characteristics and applications.

Hand Sewing Needles

Hand-sewing needles are typically used for delicate work or tasks requiring precision, such as embroidery, quilting, and appliqué.

They are usually smaller and finer than machine needles and have a pointed tip that easily pierces the fabric. Hand-sewing needles come in different sizes, numbered from 1 to 12, with higher numbers indicating finer needles.

A wide range of hand-sewing needles cater to diverse sewing needs, from delicate beading to heavy-duty upholstery projects. Each type of needle is designed with specific characteristics to suit unique sewing tasks.

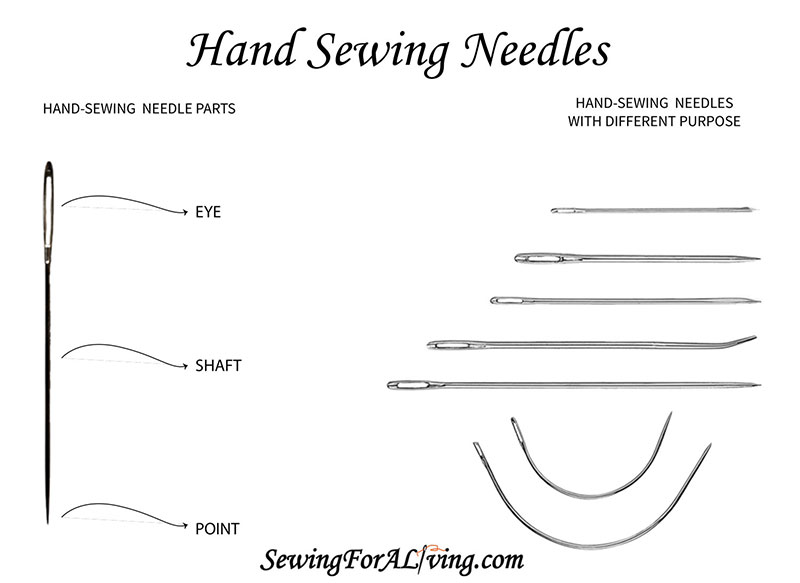

Hand sewing needles have three parts – point, shaft, and eye.

Machine Sewing Needles

Machine needles are designed for use in sewing machines. Often, they are larger and more robust than hand-sewing needles. They also have a more blunt tip that prevents them from damaging the machine and the fabric.

Machine needles come in different sizes and types, each suited for specific fabrics and sewing applications.

This article focuses on machine needles. There is much to be said about hand-sewing needles as well. I plan to do that in a separate post to keep things more organized and to the point.

Machine Sewing Needle Anatomy

To understand the differences between sewing needles, we have to start with the anatomy of the machine needle.

Here are the parts of a sewing machine needle:

Butt

The butt of the needle is the beveled end at the top. It allows for easy insertion in the needle bar of the machine.

Shank

The shank is the wider part of the sewing needle that goes into the sewing machine. Household needles have a flat shank at the back side of the needle, while industrial needles have round, threaded, notched, or other special shanks.

The shaping of the shanks allows perfect positioning of the needle in the sewing machine.

Shoulder

The shoulder is the sloping area that transitions between the shank and the blade of the needle.

Blade

The blade width determines the size of the needle. For example, a 75/11 size needle corresponds to 0.75 mm width of the blade.

Groove

The groove on the needle’s blade helps the thread smoothly glide to the eye. The groove’s length and depth depend on the needle type.

For instance, universal needles have a shorter, more narrow groove, while leather needles feature a longer, wider one. This helps the thread reach the eye efficiently, regardless of the fabric used.

Scarf

The scarf is the dented area on the underside of the blade. It helps to distribute the force of the needle and prevent it from digging into the fabric while ensuring the bobbin hook is grabbing the thread under the plate and creating a stitch.

The scarf can also vary in size and shape according to the needle type.

Eye

The eye is the hole in the needle through which the thread passes. It is shaped in a way that ensures smooth thread feeding.

Tip and Point

The tip and the point of a machine sewing needle are the parts that pierce the fabric.

Their shape, length, and size can vary according to the needle type.

For example, the point can be round, ball, or needle-shaped (cutting).

Needle type

Some needles come with color coding for the type. You can find the needle type in different places depending on the brand. Some brands color the whole shank, while some put a vertical line on the shoulder area of the needle.

The color may vary across different brands.

If the needle type is not specified on the needle, you can always find it on the needle package.

Needle size

Some brands mark the needle size on the round side of the shank as a number that shows the size in EU and US scales.

Others mark it with a color line below the type color line.

Can you use hand and machine needles interchangeably?

No. As it shows from the difference in shape and functionality, you can’t use hand sewing and machine needles interchangeably. Furthermore, you can’t use every sewing machine needle in any machine.

We’ll dig deeper into this later in this article, so please don’t get overwhelmed. I promise you will learn all there is to know about sewing machine needles in this guide.

Decoding the Needle: Identifying the Right System, Point, and Size

A sewing machine needle has 3 main parameters: system, point, and size.

Needle Systems

Sewing machine needles are classified into different systems based on the shank that connects the needle to the needle bar and the needle specifications: length of the blade, type of eye, etc.

Each needle system fits a specific type of sewing machine. Examples of needle systems include HAx1 SP, 130x705H, 110/74, and DPx5.

Sewing machine needles follow a standardized system, ensuring compatibility across most brands, including Janome, Brother, Husqvarna, Elna, Pfaff, etc. For home sewing machines, this system is 130/705 H.

Picking the correct needle system for your sewing machine is important to ensure optimal sewing performance and to prevent damage to the machine or the fabric.

To identify the correct needle system for your sewing machine, consult the manual or instruction booklet, typically under the “specifications” section. In some cases, there might be a sticker on the sewing machine indicating the system number (more often on industrial sewing machines).

To ensure compatibility, always check the needle package or consult the sewing machine manual for the recommended needle system.

However, the needle system alone doesn’t specify the needle size (blade thickness) or type of point. You can find this information on the needle packaging or on the needle itself.

Needle Sizes in Europe and the US

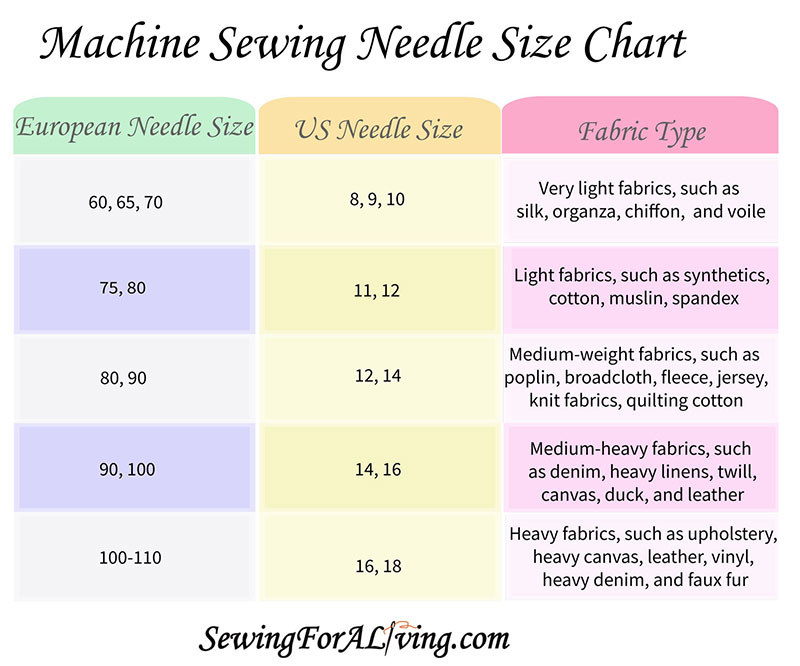

Sewing machine needle sizes are standardized internationally, but the numbering systems differ between Europe and the US. EU needle sizes range from 50 to 120, while US sizes range from 8 to 18. A higher number indicates a larger needle.

Needle sizes are determined by the needle blade size, either measured in millimeters (metric) or thousandths of an inch (US).

To illustrate, let’s take a size 70/10 needle. In the EU system, this needle has a diameter of 0.7 mm which makes it a size 70, and according to the US system has a gauge of 0.014″, which makes it a size 10.

To choose the right size needle for your sewing project, consider the fabric type, stitch type, and thread thickness. As a general rule, for lightweight fabrics, use thinner needles, and for heavier fabrics, use thicker needles.

Below you can find a table of the most common uses for sewing needles according to their size.

Needles with numbers lower than 60/8 and higher than 110/18 are rarely used in home sewing machines. You can finish almost any sewing project on a domestic sewing machine with a needle size between 60/8 and 110/18.

Needle Point

The point of a sewing needle is the sharpened end that pierces through the fabric and forms the stitch.

The point is typically made from hardened steel to withstand the force of sewing and ensure long-lasting performance. Besides hardened steel, a sewing needle can be coated with chrome, nickel, titanium nitrate, or other materials considering its purpose of use.

The shape and size of the point vary depending on the type of needle and the fabric it is designed to sew.

For instance, ballpoint needles have a rounded tip that glides smoothly through stretchy fabrics without causing puckering or damage. Sharp needles have a pointed tip that pierces through thicker fabrics like denim and canvas with ease. Cutting point needles have a unique shape that prevents them from digging into leather or suede, minimizing fabric damage.

Sewing needles are classified into two main types based on the shape of their point:

- Round points: This is the most common needle point, suitable for a wide range of fabrics, including wovens, knits, and both heavy and delicate fabrics.

- Cutting points: These have a sharp, blade-like tip that is designed to pierce through thick or dense materials, such as leather, suede, and vinyl.

Needles for different sewing machines

Regular Sewing Machine Needles

Regular sewing machine needles are designed to fit the regular household sewing machine.

They are suitable for sewing a wide range of fabrics, from light cotton to medium-weight denim. Regular sewing machine needles are typically numbered from 60 to 120 in EU sizes and 8 to 20 in US sizes, with higher numbers indicating larger needles, and come under system 130/705 H.

Serger and Coverstitch Needles

Serger needles are specifically designed for sergers, which are machines that sew multiple seams simultaneously. They have a special shape that allows them to pass through the looper thread without causing damage.

Coverstitch needles are used in coverstitch machines for creating decorative stitching, such as hems and seams with a professional-looking finish.

These extra-strong needles are specially designed to withstand the high speed of the machine with high precision.

Needles for Domestic and Industrial Sewing Machines

Sewing needles are also categorized based on the class of sewing machine they are used in. Domestic and industrial sewing machine needles come in different systems and shapes.

Domestic sewing machines typically use lighter-weight needles, while industrial sewing machines require more durable ones to handle thicker fabrics and heavier use.

Sewing Needles for Different Purposes

In this part of the guide, we will look deeper into the most common machine needles for a domestic sewing machine and their practical use.

Domestical sewing machine needles come under the system 130/705 H and can be broadly categorized as all-purpose and specialty needles.

All-purpose needles

Universal Sewing Needles

Universal needles are versatile workhorses, handling a wide range of fabrics and sewing tasks with ease.

Their slightly rounded tip ensures gentle entrance, their sharp points, and tapered shanks pierce through most materials, while their smooth eyes accommodate most thread types. Universal sewing needles work best with woven fabrics.

Universal needles are equally adept with both natural and synthetic fabrics. They can do the job whether you’re working with cotton, voile, linen, light wool, rayon, upholstery, or poplin.

Although this type of needle can handle most fabric types, you need to consider the thickness and composition of the material and pick the right size universal needle.

Ball Point Needles

Ballpoint needles are designed to glide smoothly through knit fabrics with smaller stretch percentages, such as cotton knits and knit-weave blends, without damaging the fibers or causing puckering and holes.

Their unique ball-shaped tip gently ‘spreads’ the fabric fibers apart, preventing the needle from catching and tearing the fabric.

This makes them ideal for sewing knit garments, stretchy linings, and activewear, and attaching elastic.

Ballpoint needles can be Jersey (Stretch) and Supper Stretch.

Jersey (Stretch) Needles

Jersey needles are a type of ballpoint needle for sewing jersey knit fabrics. They have a slightly smaller ball tip than other ballpoint needles, which allows them to sew more closely together and produce a smoother seam. Jersey needles are also less likely to snag or tear jersey knit fabrics.

Super Stretch Needles

Super stretch needles are for sewing the most demanding stretch fabrics, such as ultra-stretch knits, spandex, and lycra. Their ultra-fine ball tip provides exceptional glide through even the thinnest, most delicate fabrics, preventing snags and tears while maintaining a smooth, even seam.

Super Stretch Needles are best for sewing garments with extreme stretch, such as dance costumes, activewear, yoga clothing, lingerie, and swimwear.

Specialty Needles

Leather Needles

Leather needles are created for working with thick, tough materials like leather, artificial leather, and heavy non-woven synthetics.

They have sharp, durable cutting points to pierce through the material without damage, polished shanks to reduce wear and tear, and are suitable for both natural and synthetic leathers.

Leather needles are not appropriate for fabrics.

Quilting Needles

Quilting needles are designed for sewing multiple layers of fabric with ease and precision.

Their sharp, long points glide through fabric effortlessly, reducing skipped stitches and creating even, stable seams. The tapered shanks provide smooth feeding of fabric, preventing thread breakage by minimizing friction.

Quilting needles can handle most fabric types, from delicate cotton to sturdy denim. They are ideal for piecing together quilt blocks, attaching the backing fabric, adding borders, and embellishing quilts with precision.

Topstitch Needles

Topstitching needles are made for sewing through multiple layers of fabric, especially heavy ones, while making seams on the surface.

They have a large groove and eye to accommodate thick thread and a strong body to prevent breakage.

Topstitching needles are ideal for quilting seams, sewing buttonholes, and adding decorative stitching with special threads like metallic or denim threads. They can also be used for sewing denim.

Microtex Needles (Sharps)

Microtex (sharp) needles have a strong construction and a sharp point that glides easily through the fabric.

They are perfect for sewing the finest fabrics like chiffon, organza, microfiber, thin vinyl, and faux leather. Microtex needles also are a good choice for tightly woven fabrics.

Denim Needles (Jeans Needles)

Jeans needles are designed for sewing heavy-duty fabrics like denim, canvas, and upholstery. They have longer points that can pierce through thick layers of fabric and tapered shanks that minimize friction.

Denim/jeans needles are made from hardened steel to withstand the force of sewing through thick layers of fabric and thread.

They are available in different sizes and point types to accommodate different weights of denim and sewing applications. For instance, ballpoint jeans needles are ideal for sewing stretchy denim, while sharp jeans needles are well-suited for sewing heavy-duty denim and canvas.

Metallic Thread Needles

As the name suggests, metallic thread needles are a special type of needle designed to work with metallic and other special threads.

Metallic threads can be thicker and more delicate than regular sewing threads.

This type of needle can handle the stiffness and thickness of the metallic thread and prevent damage to the metallic fibers due to their sharp points and elongated eyes.

Embroidery Needles

Machine embroidery needles are designed for use with embroidery machines. They have a long, slender point that allows them to penetrate multiple layers of fabric and thread easily, producing delicate, precise embroidery stitches.

Machine embroidery needles can handle dense stitching and special embroidery threads like rayon, polyester, and cotton.

Embroidery needles are available in a variety of sizes, point types, and shank lengths to accommodate different embroidery projects and fabrics.

Hemstitch Needles

A hemstitch or wing needle is a specialized sewing machine needle, designed to create a decorative hemstitched edge on fabrics.

This type of needle has two wings on either side of the needle tip that helps to spread the fabric open and create a distinctive hemstitched pattern.

The hemstitch or wing needle is best used for light-to-medium weight fabrics that are loosely woven, such as cotton, linen, or silk, and in conjunction with a special hemstitch foot.

Double Eye Needles

A double eye needle has two eyes, stacked vertically near the tip.

The two eyes on the double-eye needle allow you to use two spools of thread at the same time. This can create a variety of effects, such as shading, texturing, and outlining. You can also use different colors of thread to create contrast and interest.

It is most commonly used for quilting and embroidery, but it can also be used for other projects, such as topstitching.

Twin Needles (Double and Tripple)

Double needles, also known as twin needles, have two needles mounted on a single shank. Their purpose is to simultaneously create two parallel stitches.

With tween needles, we use two spools of thread and just one bobbin thread to make the seams.

Twin needles have 2 sets of numbers on them – one is for the distance between the needles and the second is for the size of the needle as in single machine needles. The size mark looks like this: 1.6/70 – where 1.6 is the distance between the needles in mm and 70 is the size of the needles.

Like single needles, double needles can be different types – universal, stretch, and special.

Universal twin needles

Universal double needles are suitable for a wide range of fabrics. Double and triple needles are often used for hems, topstitching, and decorative seams.

Stretch twin needles

Stretch double needles feature a ballpoint tip that is ideal for sewing stretch fabrics.

If you are sewing knit fabrics, especially in garments that require a clean and professional finish, double needles are a valuable tool to have in your sewing kit.

The seams made with stretch twin needles resemble coverstitch seams and are often used for hems and decorative seams on knit fabric garments.

Specialty twin needles

Just like single needles, twin needles can have special functions. You can find the following variations of tween needles to upgrade your sewing kit:

- Metallic Twin

- Embroidery Twin

- Jeans Twin

- Double Hemstitch

Most of the above have two special needles on the shank. The double hemstitch needle is an exception as it consists of one wing needle and one universal needle on the same shank.

Choosing the Right Needle for Your Project

Here are some general guidelines that can help you pick the right needle for your project.

The type of needle you choose will depend on each of these factors: the fabric you are sewing and its thickness, the thread, and the sewing task.

Here are the factors to consider when selecting a needle:

Fabric type

Different fabrics require different types of needles. For example, knit fabrics should be sewn with ballpoint needles, which have a rounded tip that prevents them from damaging the fabric. Denim and other heavy-duty fabrics should be sewn with jeans needles, which are made from hardened steel and can pierce through thick layers of fabric.

Thread type

The thickness of your thread will affect the size of the needle you need. Thicker threads require larger needles. Some special threads (like metallic) require special needles.

Sewing task

Different sewing applications require different needle types. For example, topstitching and quilting require sharp needles that can produce crisp, clean stitches. Hemming and decorative stitching may require ballpoint needles, which prevent puckering and produce a smoother finish.

As a general rule, choose the needle type according to the fabric type and the sewing task, and the choose the needle size according to the fabric and thread thickness.

Here are some general guidelines:

- Use a sharp, fine needle for delicate fabrics, such as silk and voile.

- For light- to medium-weight woven fabrics, such as cotton and poplin, use a universal sewing machine needle.

- For stretch and high-stretch knit fabrics, use a ballpoint needle (jersey or super stretch).

- For heavy fabrics, such as denim and upholstery, use a heavier-duty or denim needle.

- For serging, use a serger needle.

- For cover-stitching, use a coverstitch needle.

Sewing Thread and Needle Compatibility

In addition to choosing the right needle, you also need to make the right needle and thread combination. To do that, you need to make sure that the thread passes freely through the needle’s eye. The ideal combination is for the thread to fill about 70% of the eye.

If you have any doubts, here is a quick test that you can do to pick the right needle and thread combination.

To test if the thread and needle are a good match, attach a longer piece of the thread to the needle and hold it vertically.

- The needle will drop to the bottom of the thread if it is too big.

- If the needle is too small, it will remain at the top of the thread.

- The needle will gradually spiral down the thread if it is the correct size.

How Often Should I Change My Needle?

The frequency with which you need to change your sewing needle depends on several factors, including the type of fabric, the type of thread, the stitch length, and the amount of sewing you are doing.

However, as a general rule of thumb, it is a good idea to change your needle every 8-12 hours of sewing.

Here are some signs that it is time to change your needle:

- Skipping or uneven stitches: This is the most obvious sign that your needle is worn out. If your stitches are skipping or not forming correctly, it is time to change your needle.

- Thread breakage: If your thread is breaking frequently, it could be a sign that your needle is dull or damaged. Change your needle to see if it solves the problem.

- Puckered or damaged fabric.

- Build-up: Over time, wax and oil build-up can accumulate on your needle, which can interfere with stitching and cause the needle to break. Clean your needle regularly to remove build-up, especially if you work with special fabrics.

- Dull or bent tip: If you notice that the needle has a dull or bent tip, change it. A dull tip or a broken needle can lead not only to skipping stitches but can also damage the sewing machine.

- A popping sound made by the sewing machine.

When you have any doubts about the condition and quality of the needle, go ahead and change it. This can save a lot of trouble.

How to insert sewing machine needles

Here’s a step-by-step guide on how to insert sewing machine needles:

- Power off the sewing machine. This will prevent any accidents and ensure that the needle doesn’t move while you’re inserting it.

- Identify the needle insertion slot. This is usually located on the top of the machine, above the feed dogs. Raise the needle to the highest position. This way you are going to have enough space to change the needle.

- Loosen the needle screw by turning it counterclockwise (toward you).

- Remove the old needle.

- Grasp the needle firmly by its shank. Do not touch the needle tip, as this can damage it and you.

- Align the needle with the needle insertion slot. Make sure the needle is pointing upwards and that the flat side of the shank is facing the rear of the machine. The eye of the needle should look straight ahead.

- Gently push the needle into the slot until it is fully inserted.

- Turn the needle screw clockwise to tighten and fix the needle firmly in place.

- Thread the needle and adjust the tension.

Care and Maintenance

Proper care and maintenance of your sewing needles will extend their lifespan and ensure they continue to perform at their best. Here are some tips:

- Store needles in a safe place to prevent them from bending or breaking.

- Wipe needles after each use to remove dirt and debris.

- Replace needles regularly, especially if they become dull or damaged.

- Make sure the needles you are using have the right system, type, point, and size.

- Make sure you are using a high-quality needle.

Common Problems and Solutions

If you experience frequent problems with the needles, here is a list of possible problems that can be the reason for your troubles:

- You might be pulling the fabric as you sew. Or, you might be pulling the thread too hard as you pull out the fabric from the sewing machine. Both of these bad sewing habits can damage or break the needles you are using.

- The needle might not be inserted properly. It might not be under the right angle, not the right system, or not all the way into the machine slot.

- The needle is touching the feed dog plate or other parts like the foot. This might be due to a loose foot, bobbin, or a sign that you need to have your machine checked by a technician.

- Your sewing machine might need cleaning. There can be pieces of old broken needle tips, small pieces of thread, or dust stuck in the feeding dogs, bobbin, and other parts of the machine.

- The thread size might not match the needle eye size.

In Conclusion on Sewing Needles

Sewing needles are an essential part of the sewing machine, that need proper care, maintenance, and use.

By understanding the different types of needles and their specific uses, you can ensure that your sewing projects are always stitch-perfect.

I hope this guide leaves no unanswered questions and makes you a bit more confident about your sewing knowledge and skills. If you want to share something on this topic, please leave a comment below.

Like what you read here? Support my site

Hi sewing friends, Daniela here! As a passionate sewist and pattern maker, I love to empower fellow creators to sew their dream wardrobes. Join me on a fun journey where we unlock our creativity, stitch by stitch.

If this tutorial has helped you, please consider supporting the blog with a small donation. This way I can keep it up and continue sharing for free.

It is always greatly appreciated!

I hope you enjoyed this pattern-making lesson. Happy sewing!

Related posts:

- How to sew buttons and buttonholes

- Free online sewing classes for beginners

- Types of zippers – what you need to know

- Learning How To Sew (and why you should)

SIGN UP FOR SEWING FOR A LIVING NEWSLETTER

If you like what you read here, join our mailing list so we can send you our new sewing tutorials, pattern-making lessons, patterns, and some occasional offers that we think might interest you!

We will protect and use your data following our Privacy policy.

You may unsubscribe at any time by clicking the link in the emails we send.